REME

|

The Royal Electrical and Mechanical Engineers made a significant contribution to Operation and Post Crown. From the start of the project to the end, the REME repaired a great variety of broken machinery. From D8 Caterpillars, Gainsboroughs, Euclids and Michigans, to the Howard Train. From giant Scammel transporters to Commer tippers the fitters and mechanics kept the machines working. Recovery Scammells with their Driver Mechanics traveled the dirt roads between Crown and places like Nakom Phanom, Korat, Roi Et and Bangkok. They accompanied the RCT Scammell lowloaders to and from Bangkok docks ensuring delivery of the large plant machinery over dirt roads and rickety wooden bridges for hundreds of miles. Specialist storemen sourced obscure replacement parts for unusual machinery. |

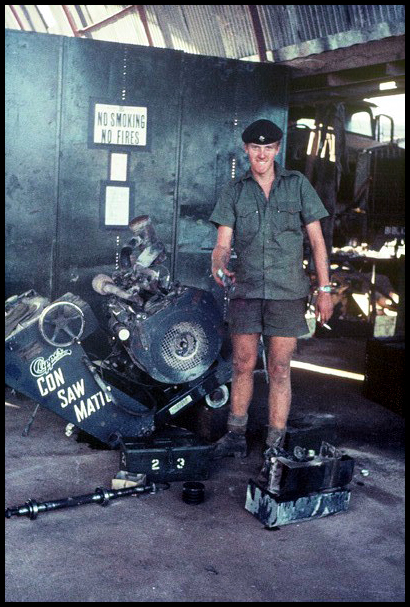

John Lloyd was a vehicle mechanic but his workload was varied as he repaired whatever machine was put in front of him. He worked on repairing the Howard Train for example and this cutting saw . Here's his account of the job. "The machine is a ‘Clipper Con Sawmatic’ used to cut expansion joints in the concrete runway pavements. They first put soft board in the joints between the slabs then raked it out to pour bitumen in. They changed this to casting a continuous pavement and cut the joints by using the 18inch diamond blade in the diesel powered floor saw. As you can see this machine came in for repair to the drive shaft (lying on the floor near the tool box) the bearings had worn out due to lack of grease. On the way to the workshops in the back of a tipper truck, the tailgate was insecure and the machine fell out damaging the manifold and cylinder head. Urgent signals were sent to the UK for the parts, which took about seven days to come. These were vital pieces of kit of which there were only two in the Far East at this time.

In 1966 concrete cutting was in its infancy and the 18inch diamond impregnated blades very expensive. Today they would cost about £100/150 for a premium blade, in 1966 it would have cost around £400/500. Near the ordinance store there was a pallet full of blades, a lot of money lying around". |

|

|

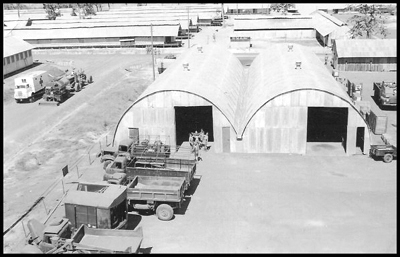

The REME vehicle workshops stood opposite the Medical Center on the 54th Street forming the westerly boundary of the REME compound. This picture shows in the left foreground, three Commer tippers a Coles Crane cab minus the latticed boom and possibly a Morris Welding Truck nearest to the doors. |

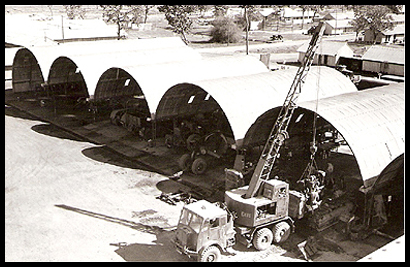

The Plant Workshops look pretty much full to capacity as a Coles Crane lifts a Caterpillar D8 engine for the fitters to work on. The amount of wear and tear on the plant was massive as they were worked to breaking point in the harsh conditions. |

|

|

Cpl Mick Burgin's section of 3 troop 59 Fd Sqn, work on the base structure of the soon to be RAOC offices. The Plant Workshop Romney Huts in the background, are under construction by 2 Troop RAE 11 Indep Fd Sqn RE circa Feb/March 1964. |

Two Explorer recovery Scammell's travel the dirt roads of Thailand. This shot was taken from the cupola of the lead Scammell. |

|

|